Precious Metal Recovery

We recover precious metals from various forms of materials. Your sample materials will be first sent over to our in-house Lab facility for analysis. Our Lab uses a mix of drying, pounding, processing, screening, and partitioning strategy to plan agent tests for the concoction process and decide the metal content by utilizing Inductive Coupled Plasma (ICP- OES). After various tests conducted, we will then determine the best recuperation procedure for your materials. E-waste recycling is sustainable for the environment and reduces the reliance on mining for raw materials. MAEH purpose their technology to serve as an e-waste recycling company to promote a circular economy.

Incineration Process

This process is designed for materials that couldn’t directly treat with only a chemical process. (eg. Resin, Filters, sludges, wipes, wafer die attached with plastic) Through incineration, a better reaction surface is achieved in the ashes form and therefore more efficient for further precious metal extraction.

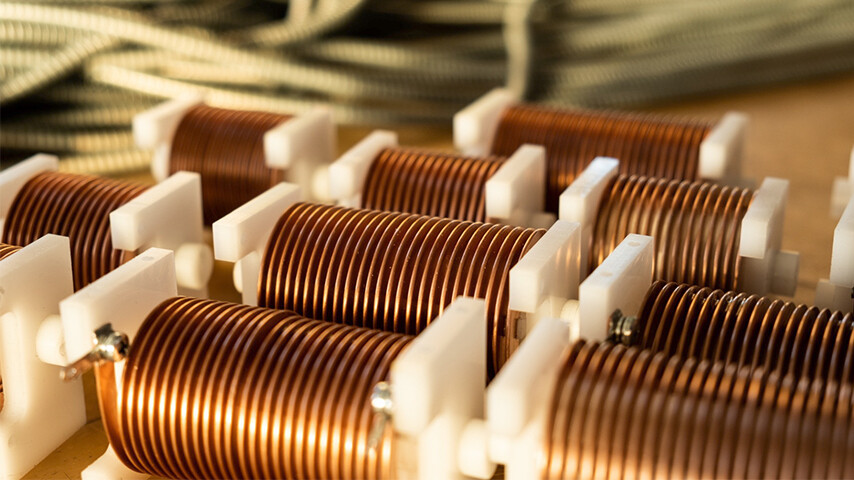

Chemical Process

Cyanide leaching removes gold from materials with surface or visible gold (eg. LED Lead Frame, connector, Shield, Target, PCB Board, etc.). As this process involves cyanide, all relevant safety and security measures are strictly implemented and adhered to for maximum safety to operators and the environment. Materials are loaded into titanium barrels and then immersed into a cyanide-based solution for the particular evacuation of surface gold. The resulting gold-saturated solution is then sent for electrolysis for further gold recovery.

Acid leaching extracts precious metals that are embedded in solid electronic scraps. Materials are fed into the reaction tank where they are dissolved. The precious metals present in the liquid are then extracted by selective precipitation. Electrolysis recovers gold from gold-saturated solutions. Gold present in the solution is plated onto the cathodes. The resulting gold akes are then removed from the cathodes for further recovery & refinery.

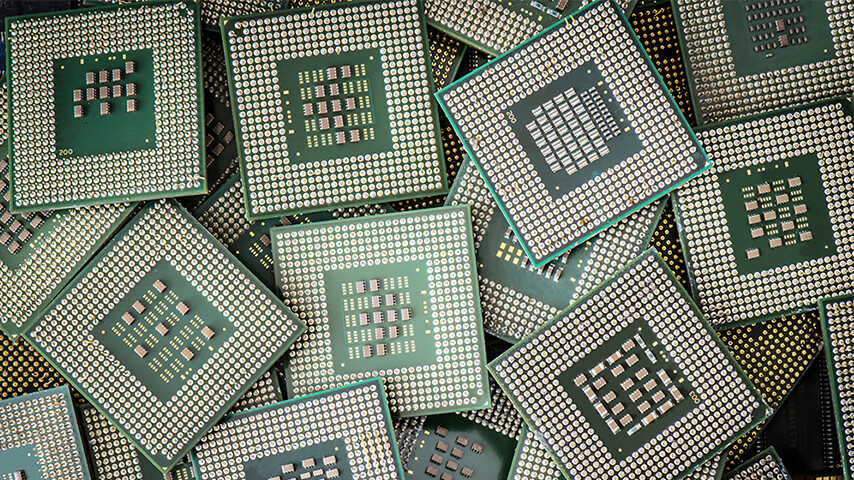

CPU

Mobile Phone

Connector

Circuit Board

Metal Scrap

Gold - AU

Silver - AG